Rugged Board-to-Board Connectors for Harsh Environments

Connector Selection for Industrial, IoT, and Transportation Systems

The reliability and efficiency of industrial, IoT, and transportation systems depend on selecting the right connectors to ensure consistent power, reliable signal transmission, and mechanical stability, even in the harshest environments.

Connectors should be viewed as a cornerstone during system design, not as a passive component. The right selection involves many factors, such as size, durability, data transmission capabilities, and environmental resilience.

Rugged Environments Require Robust Connectors

In rugged environments—factories with heavy machinery, outdoor sensors on smart farms, or transportation hubs with high vibration and temperature swings—connectors must offer robust environmental sealing, withstand mechanical stress, and support long life cycles without failure.

Industrial and transportation applications, such as automated factory lines, rail networks, and autonomous delivery, must often operate 24/7 in demanding conditions. If the connectors selected aren't built to withstand harsh conditions and repeated mating cycles, the results may include costly rework, premature failure, and unhappy customers. A poor-quality or mismatched connector can cause intermittent faults, degraded signals, or total system failure.

Complexities of IoT Applications

IoT applications add additional complexity as devices become smaller and more distributed, requiring compact connectors that don’t sacrifice performance. Shielding and precise impedance control are essential for signal integrity, especially in high-speed applications.

Flexibility for Evolving Product Lines

A connector family that supports various pin counts and form factors provides flexibility as product lines evolve, whether from adding modules to a factory control system or upgrading an IoT device with additional sensors.

The Harwin Kontrol M55 Series

Harwin offers a broad portfolio of rugged board-to-board connectors with cable-to-board flexibility, providing designers with robust options for a wide range of applications.

Key Features of the M55 Series

- Pitch: 1.27 mm

- Fully shrouded connectors assist with blind mating and protection from lateral and twisting forces caused by vibration

- Designed to withstand vibration forces equal to 20 times the force of gravity (20 G)

- Supports a minimum of 500 mating operations

- Operating temperature range: -55°C to +125°C

- Supports data transmission speeds up to 3 Gb/s

Connector Options

The M55 series is available in multiple configurations, including:

- M55-6002042R: A vertical socket with 20 contacts in a 10 + 10 configuration, ideal for mezzanine board stacking with a low profile of 6.25 mm above the PCB.

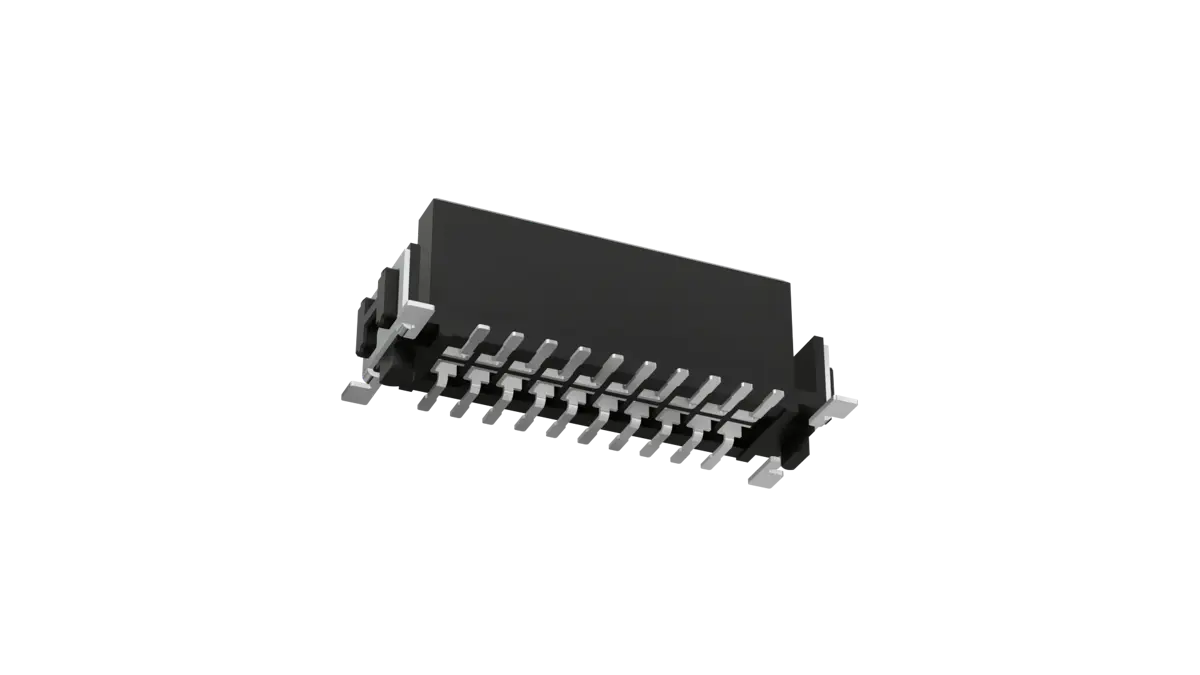

- M55-7108042R: A right-angle, surface-mount header with an 80-contact layout for modular or co-planar applications.

- M55-8201242: A 12-contact double-row female IDC cable connector, ideal for dynamic industrial and IoT environments, accepting 30 AWG ribbon cable.

Visual Examples

Figure 1: The Harwin Kontrol M55-6002042R, ideal for mezzanine board stacking. (Image source: Harwin)

Figure 2: The M55-7108042R right-angle, surface-mount header. (Image source: Harwin)

Figure 3: The M55-8201242 IDC cable connector accepting 30 AWG ribbon cable. (Image source: Harwin)

Conclusion

Connector selection plays a foundational role in ensuring mechanical resilience and electrical reliability for industrial and embedded systems. The Harwin Kontrol M55 series provides design flexibility and scalability for robust, future-ready industrial and embedded systems.